The 2025 Hannover Metalworking World Expo (EMO Hannover 2025) will be held from September 22 to 27 at the Hannover Exhibition Center in Germany. As a premier global event in the metalworking and manufacturing technology sector, this year’s exhibition is themed "Innovation Hub for Smart and Sustainable Manufacturing," focusing on the integration of digital production, resource efficiency, and cutting-edge processing technologies.

EMO 2025 will bring together industry leaders from 45 countries/regions and is expected to attract professional visitors from approximately 140 countries/regions worldwide. The exhibition comprehensively showcases the breadth and depth of international manufacturing technology, providing a vital platform for the global manufacturing industry to gain insights into future trends and access advanced technologies and solutions.

During the event, exhibitors and visitors with extensive expertise will engage in in-depth discussions on major manufacturing trends, exchange innovative ideas with representatives of international production research, and collaboratively develop solutions for the industry’s current challenges.

We look forward to meeting you at Booth C52 in Hall 4!

About YongPu

Suzhou Yongpu Precision Technology Co., Ltd., established in 2013, is a high-tech enterprise specializing in the production of precision tools and metal-cutting technical services. The company is headquartered in the Wujiang Economic Development Zone in Suzhou, with manufacturing bases in Suzhou and Chengdu, as well as three regrinding and coating centers. Leveraging a strong R&D team, Yongpu has built a comprehensive round-shank tool product line, including solid carbide hole-making tools, milling tools, precision threading tools (taps), and PCD precision tools. The company is committed to becoming a one-stop comprehensive service provider for round-shank tools.

Suzhou Yongpu Precision Technology Co., Ltd. is a wholly-owned subsidiary of the Yongpu Group, which entered into a strategic acquisition with Sandvik Coromant in July 2021. The Yongpu Group is dedicated to the R&D and production of carbide rods, precision tools, and precision coatings. As a manufacturer and service provider of high-quality carbide materials, precision tools, and precision tool and mold coating services, Yongpu possesses a full industrial chain for precision round-shank tool manufacturing. Every環(huán)節(jié) offers advantages in custom non-standard solutions, meeting diverse customer needs. Yongpu’s production facilities are equipped with various high-end imported equipment and manufacturing process inspection devices, continuously improving quality management objectives and certified by the German TUV ISO9001 Quality Management System. Adhering to the operational philosophy and values of "Integrity, Collaboration, Professionalism, and Progress," and supported by Sandvik’s century-long technological expertise, the Yongpu Group focuses on continuous innovation and R&D in round-shank tools, expanding its precision tool product line to provide comprehensive precision tool solutions and tool management services for the manufacturing industry. Its products are widely used in high-end manufacturing sectors such as automotive, aerospace, engineering machinery, mold manufacturing, energy and environment, medical devices, and industrial machinery.

YongPu Products

High-Performance Hole-Making Tools

Focusing on niche industries, providing overall hole-making part solutions, such as wheel hub units, crankshafts, steering knuckles, and other solutions.

Precision threaded tool

Focusing on the subdivision of the materials to be processed, we provide high-precision and high-quality threaded tool solutions.

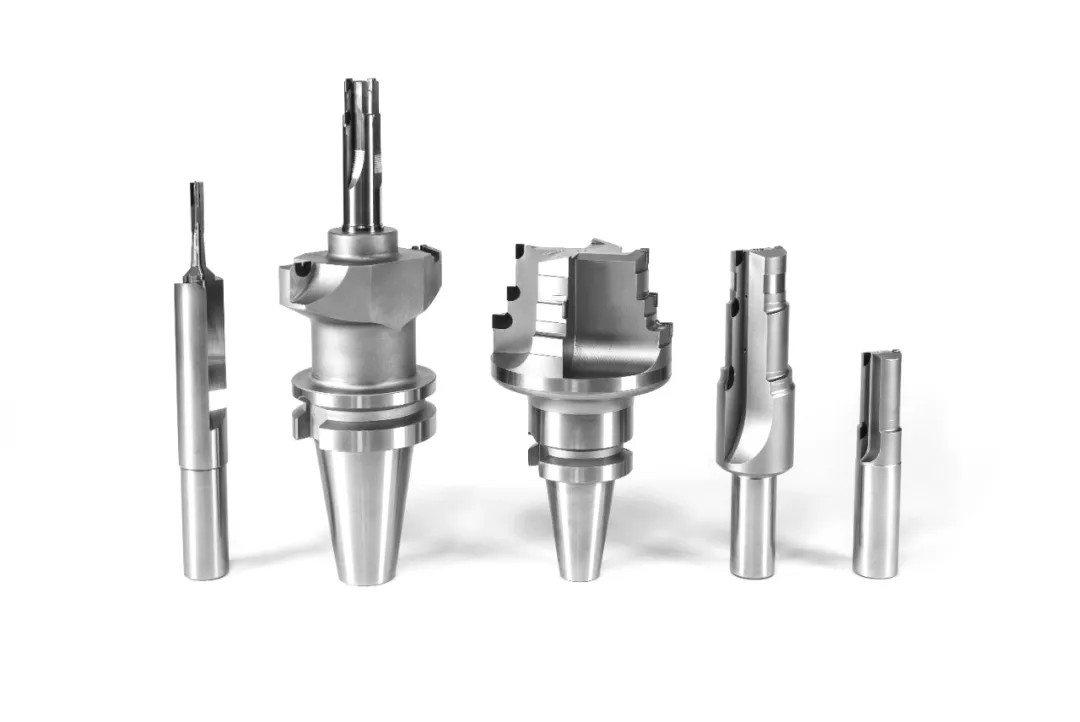

PCD composite precision tool

PCD composite precision tools have unique advantages in efficient and high precision in processing aluminum alloys and composite parts. Using Pure Precision can provide an overall part tool solution based on PCD tools, as well as efficiency improvement solutions.

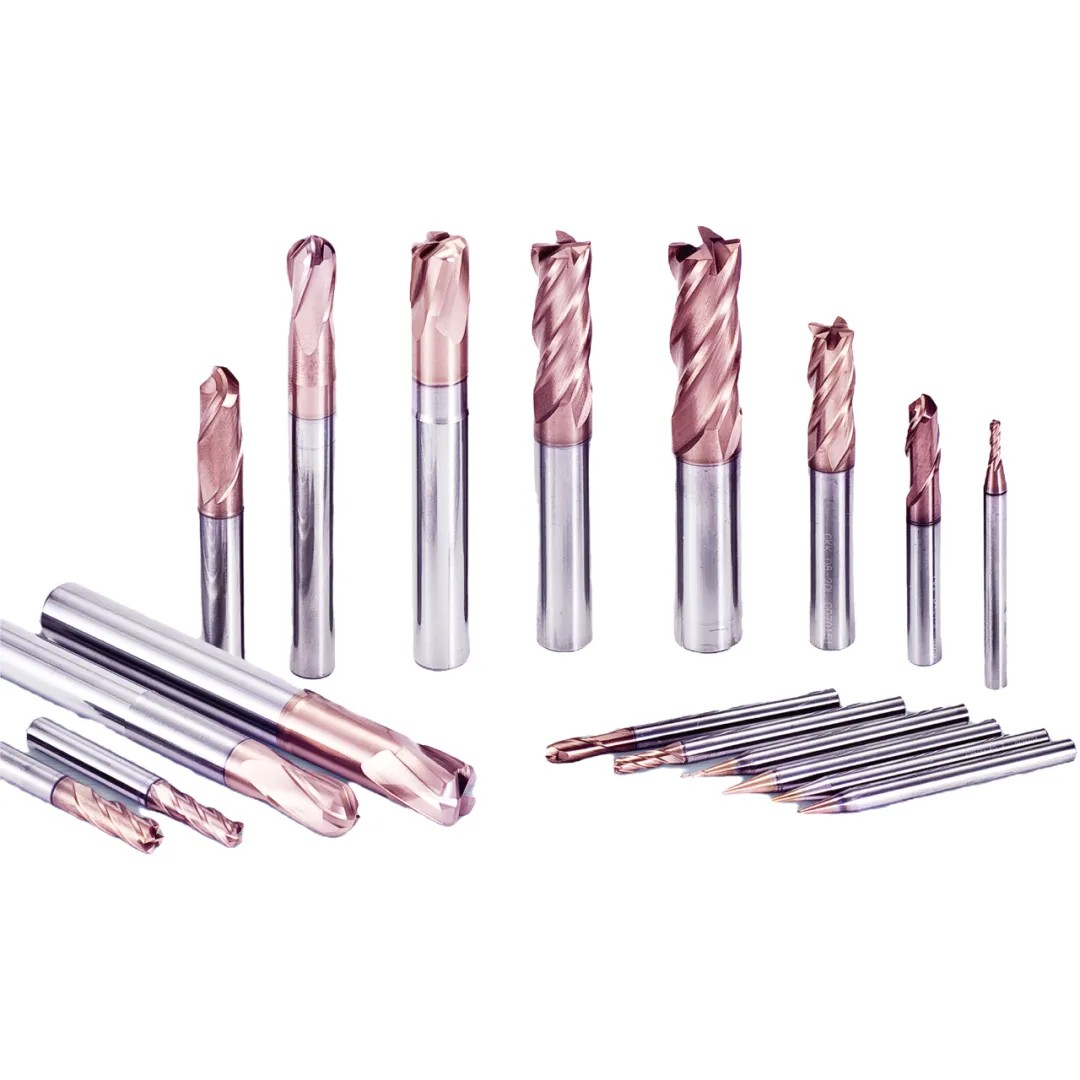

High-performance milling tool

Relying on Sandvik's technical support, based on years of experience in deep cultivation of milling tools and whole pack of aviation customers' tools. We have developed efficient milling tool solutions for aviation, military, medical, mold and other industries, and provide application support.

Non-standard tool solutions

UP Precision provides you with various non-standard tool solutions. Our tool experts and application engineers will communicate with you in detail, thereby formulating proprietary non-standard solutions to help you improve processing efficiency and reduce costs.