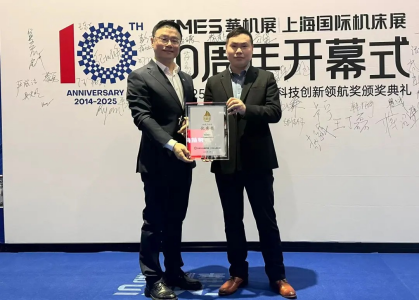

The "Leading Award for Science and Technology Innovation in the Machinery Industry" is a comprehensive science and technology award for the machinery industry established by the Machinery Industry Information Research Institute and the German VDI Group. It aims to commend organizations that have made outstanding contributions to the science and technology innovation activities in the machinery industry. This award ceremony is also one of the important activities of the 10th Shanghai International Machine Tool Exhibition.

Awards-winning knives introduction

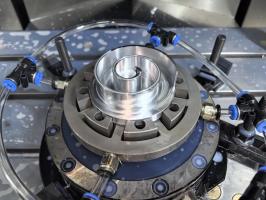

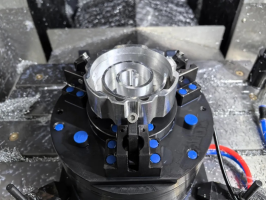

PSM milling cutters are made of hard alloy substrate, with high-precision PCD cutter pockets machined on the substrate, and long PCD cutters welded on the pockets, and then specially treated by a five-axis laser machine. This ensures that the diameter tolerance of the cutter is within 0.006MM, which, compared with traditional hard alloy + coated cutters, can achieve better milling quality, higher processing efficiency, and greatly improve the life of the cutter.

It is now stable in use by many customers, and its performance is particularly stable and reliable. Especially for those customers with strict requirements for the perpendicularity, profile, and roughness of parts, PSM vortex compressor static and dynamic disk milling cutters are their best choice.

Part picture

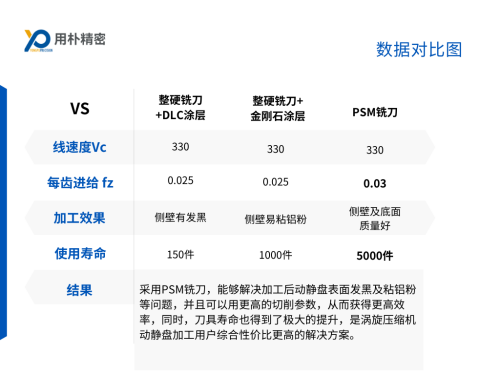

The following is a comparison of actual use data with traditional hard alloy + coated cutting tools:

Summary

Adopting PSM milling cutter can solve the problems of blackening and sticking of aluminum powder on the surface of the dynamic and static discs after processing, and it can also use higher cutting parameters to obtain higher efficiency, and the tool life has also been greatly improved, which is a more cost-effective solution for the processing of the dynamic and static discs of the scroll compressor.