Single blade breakthrough of 1300 holes! Excellent performance of using precision drill bits in machining ductile iron

時間:2025/6/20 關(guān)鍵詞:YongPu Precision, Cylinder Head, And Vermicular Graphite Cast Iron 瀏覽量:133

Case Data Summary

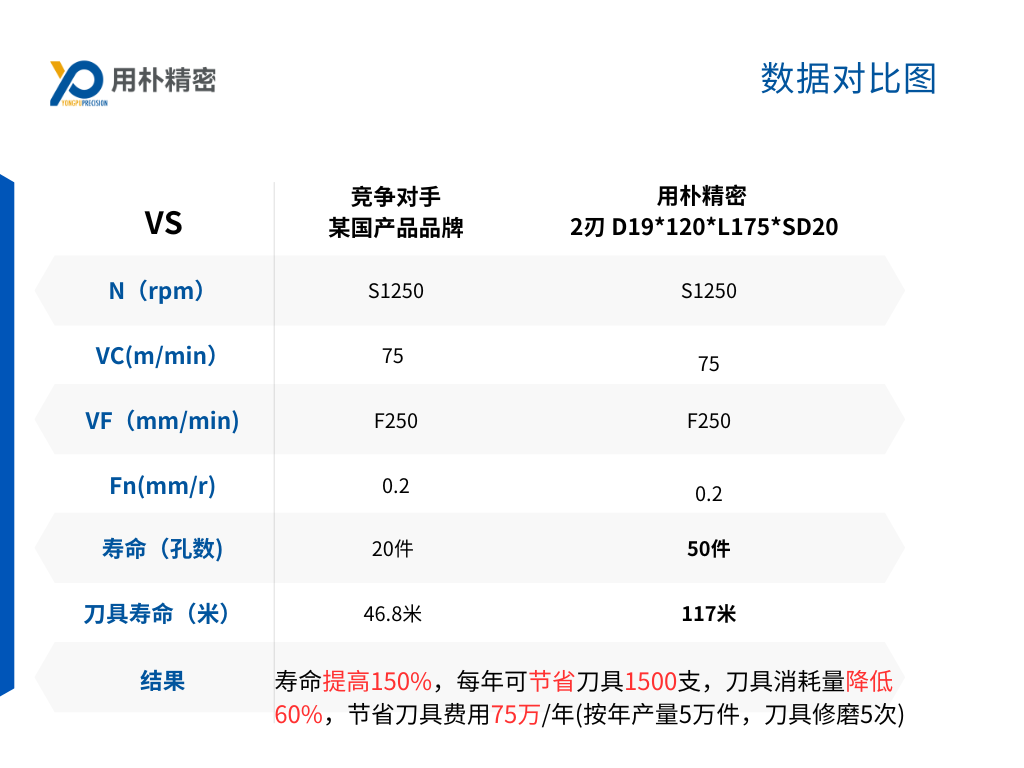

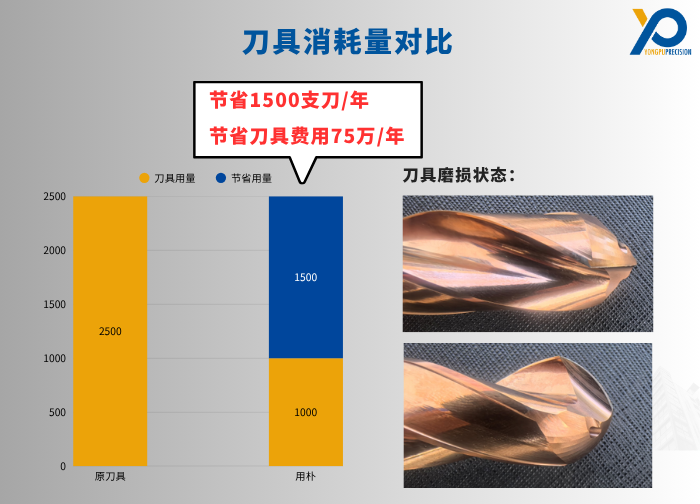

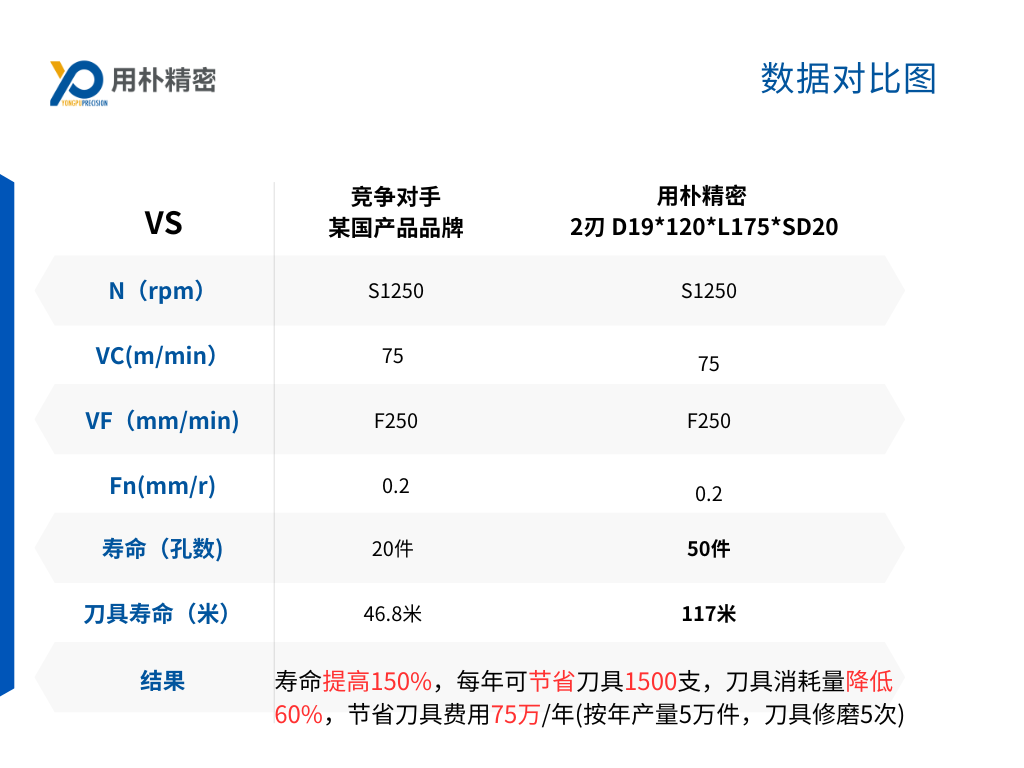

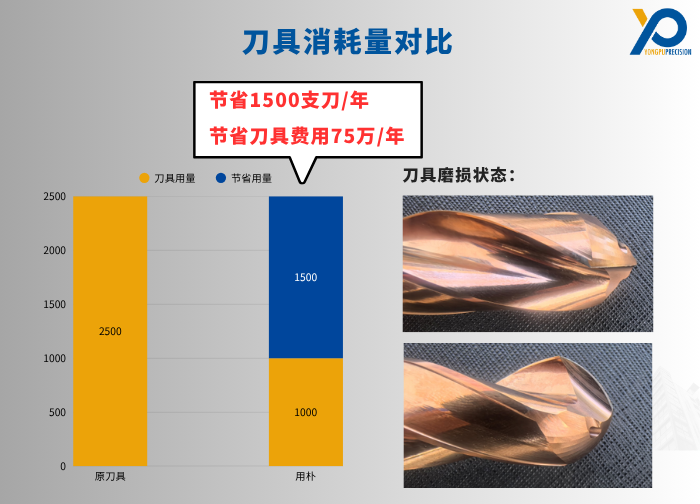

This case study shows a 150% increase in the life of Pekin Precision Drill bits, which is 2.5 times that of competitors, saving customers 50 hours of刀具 change time per year and saving on drill bit purchase costs: 750,000 yuan per year! For more details, see the description below:

Product, condition, tool description

-

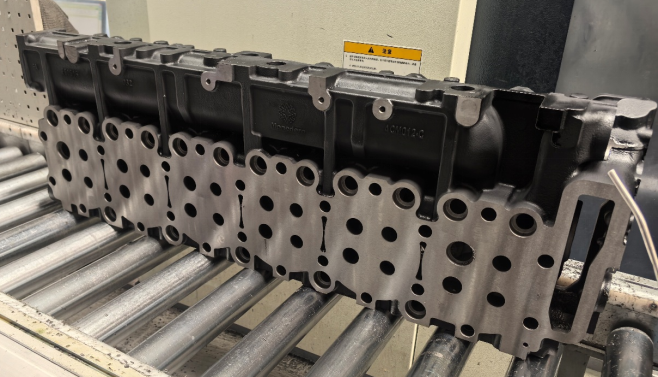

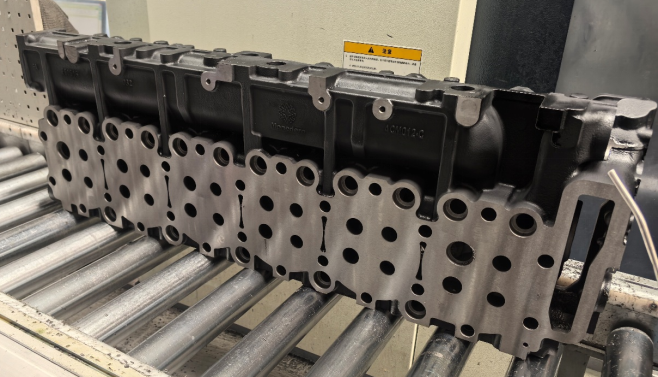

Workpiece name: cylinder head

-

Workpiece material: RuT450 (200-250 HB)

-

Processing operation: drilling 26-D19(+0.21/-0.06) through hole to size, hole depth 90mm

-

Processing equipment: MAKINO-vertical machining center

-

Cooling method: emulsion, internal cooling

-

Main shaft type: BT50

-

Tool柄 type: Thermal expansion tool handle

-

Tool specifications: 2-blade D19*120*L175*SD20; hard alloy material; internal cooling.

Application Status

Core advantages

-

Reduced cost of replacement: Extend tool life, reduce the frequency of tool changes, and reduce downtime;

-

Production capacity enhancement: Saving time can increase production or shorten lead times;

-

Enhanced competitiveness: lower costs, higher profits;

-

Quality improvement: Significant improvement in the quality of the hole, meeting customer requirements;

-

Enhanced stability: Minimal wear, safe control, and support for smart factory initiatives;