Share with you a successful case of a comprehensive solution for hole machining of shaft parts:

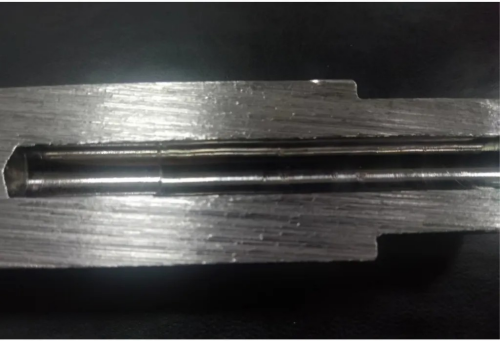

▲照片 of the sectioned part of the processing

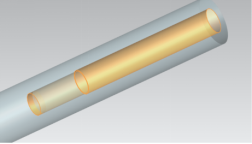

▲X-ray view

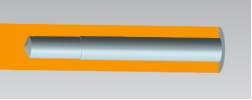

▲ Sectional view

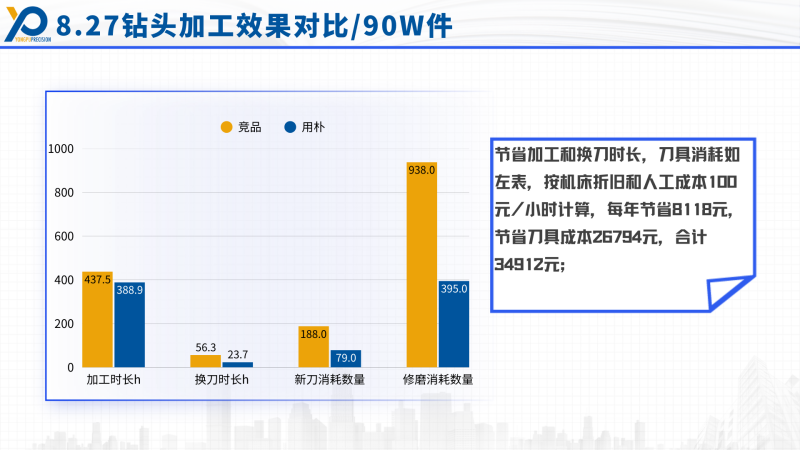

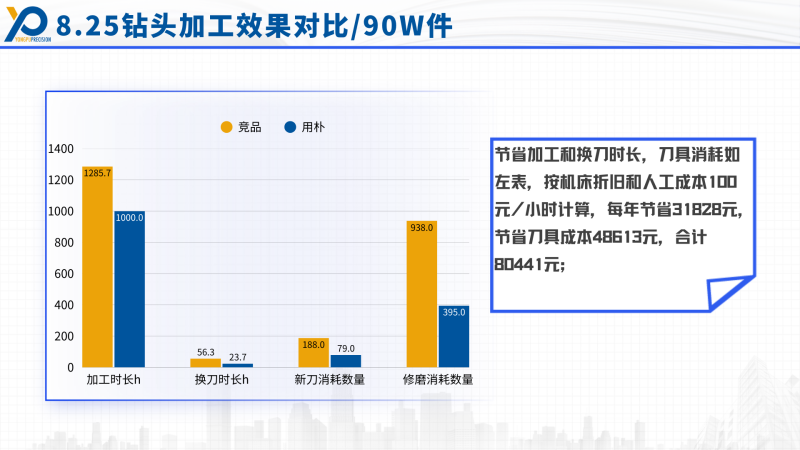

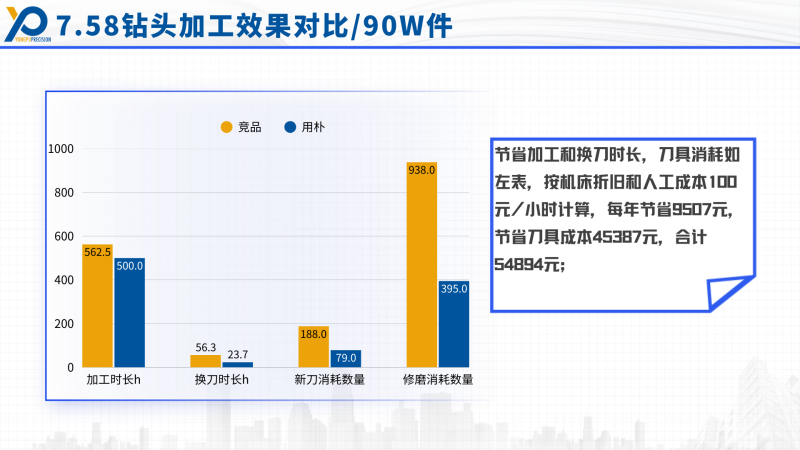

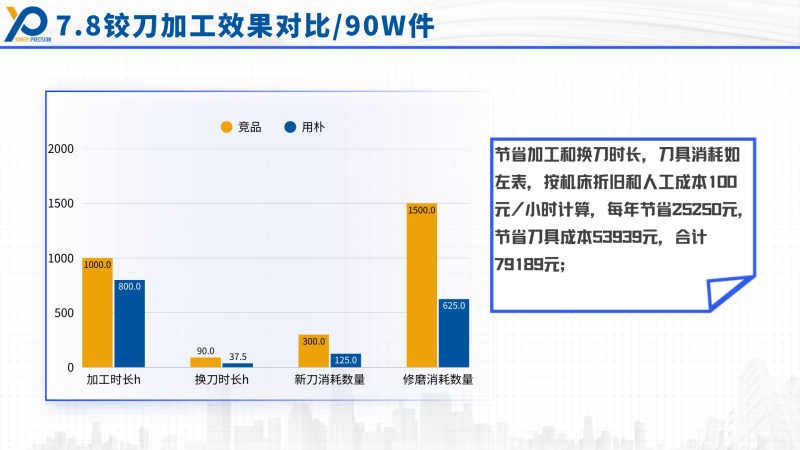

The overall solution of Puk Precision can effectively improve the processing efficiency, not only greatly improve the tool life, but also reduce the tool change time. Below are the results calculated based on one production line with an annual output of 900,000 pieces:

Saving processing time:747.1 hours;

Saving about 74,703 yuan in machine tool depreciation and labor costs;;

Savingabout 174,733 yuan in tooling costs;

Save about 249,436 yuan in total;

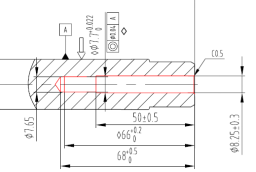

Workpiece information

Product Name: Coupling;

Material grade:40Cr;

Material hardness: HRC22-28;

Processing requirements:D8.25 and D7.7 holes with coaxiality of 0.04, wall roughness of D7.7 hole Ra1.6;

Processing equipment: horizontal lathe, emulsion fluid internal cooling, spring chuck clamping;

Production:900,000 pieces/year;

Design features of the plain knife

Here are photos of the cutting tool and the machining parameters, as well as a comparison with the competition:

8.27 Pilot Drill: Pilot hole depth 14mm

8.25 Deep hole drill: Drill depth 36mm

7.6 Deep hole drilling: drilling holes with a depth of 18mm

7.6 Deep hole drilling: drilling holes with a depth of 18mm

Conclusion

The drill bit life is 237.5% of the competition, and the reamer life is 240% of the competition, solving the problem of the customer's original reamer roughness unqualified.

Using Pu Precision's comprehensive solution for hole machining of shaft parts, it can greatly improve your production efficiency and reduce processing costs.