There are a variety of drill bits used in mechanical drilling.Drill bit types include solid carbide bits, replaceable bit heads, blade bits, and gun drills.

The whole hard alloy drill bit can be subdivided into micro-drills, shallow hole drills, deep hole drills, etc., according to the diameter and hole depth. These drill bit combinations bring a wealth of choices to drilling processing and thus achieve the maximum range of application coverage.

In this paper, we will talk about a very special application of drilling processing - Deep hole drilling. For drilling applications, the depth of the hole is defined as the multiple of the diameter of the hole, such as 3 times diameter, 5 times diameter, or 8 times diameter, etc., which belongs to the scope of shallow hole drilling. When the hole depth is greater than 8 times the diameter, it enters the scope of deep hole drilling. Generally speaking, 10-40 times the diameter is the application field of the whole hard deep hole drilling, and it is better to use a gun drill when it exceeds 40 times the diameter.

Deep hole drilling processing, for the design and application requirements of the drill bit are extremely high.

Application requirements, such as:

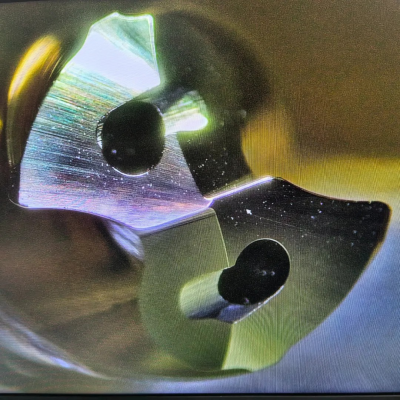

Special consideration is required for the design of deep hole drills, such as:

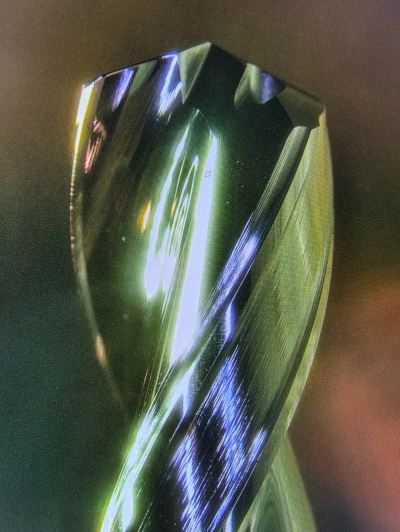

Hard alloy deep hole drill

Deep hole machining is very common in the field of mechanical processing and is widely used in industries such as automobiles, petroleum and natural gas, energy, shipbuilding, etc. Typical parts in these fields include diesel engine crankshafts, oil well valve bodies, ship engine connecting rods, wind turbine main shafts, etc.

Take the crankshaft of a diesel engine as an example, the most critical machining difficulty lies in the drilling depth and its consequences, the drilling depth is usually 10 times the diameter or more. Especially for steel crankshafts, the drilling depth is the most likely to have problems, because it is required to discharge smoothly and clean, and how to deal with the long spiral chips formed at the outlet when machining through holes is a more difficult problem. Moreover, chip removal is generally more difficult when machining deep holes.

According to the difference of application field and workpiece material, people have developed various types of cutting fluid, including: pure oil, emulsion and micro-oil mist lubrication (MQL), here we want to emphasize MQL in particular, because this way is relatively friendly to the environment, not only to reduce the consumption of cutting fluid and reduce the cost of later maintenance, but also to reduce the harm to the environment and personnel. Any matter has its multifaceted nature, MQL sometimes causes too high cutting temperature, which will reduce the overall performance of the cutting tool, and we need to find a way to avoid this defect.

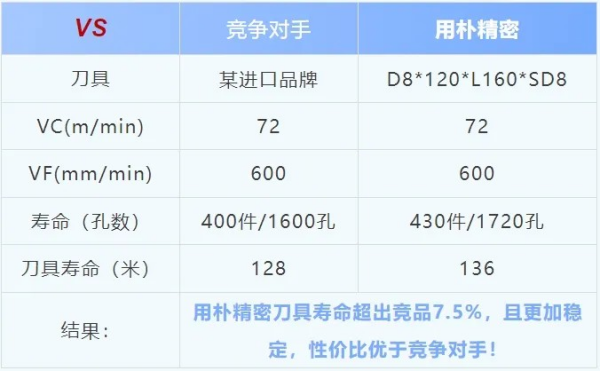

Today, we are increasingly convinced that reducing the cost of machining and achieving the expectation of unmanned black factories, we have designed a new generation of deep hole drills that meet the requirements of improving efficiency and reducing costs, and have received widespread market recognition.

Tool design: