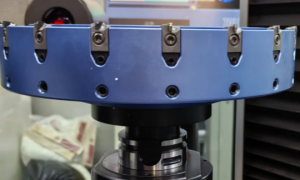

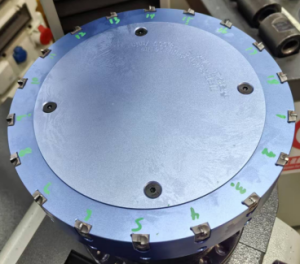

In the manufacturing of car engine, the processing of cylinder block/cylinder head has always been a difficult "bone to chew", especially for the high requirements of roughness and flatness of the upper and lower large surfaces, and the strictly limited parallelism requirements between the upper and lower surfaces, which has caused a lot of trouble for many machining enterprises. Good news is coming, using Pukjing to launch a solution to this problem, the D250 PCD face milling cutter! It is a "new star" in this field with its innovative design, extremely high efficiency and flatness, mirror-like surface roughness. Let's take a deep dive into this "godsend" and see how it can help you achieve efficient machining!

1. Overall characteristics

01. High abrasion resistance

This "sacred weapon" uses PCD cutting blades, which have a hardness second only to natural diamond, significantly increasing cutting speed and reducing tool wear, especially suitable for processing adhesive materials such as aluminum alloys and magnesium alloys, thus extending the life.

02. Ultra-high surface quality

PCD cutting blades are equipped with very sharp edges to achieve mirror-like processing, resulting in a surface without burrs, eliminating the need for subsequent polishing, greatly saving the time for deburring after processing.

03. Ultra-high cutting speed

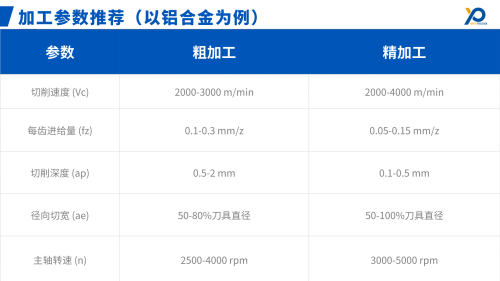

The knife body that has been dynamically balanced and the PCD knife blade that can withstand high temperatures, with a cutting speed of (2000-4000 m/min), greatly improve production efficiency.

04.Anti-deposit

PCD surface is smooth and the cutting edge is sharp, which reduces the cutting heat and greatly reduces the adhesion problem common in the processing of aluminum alloys.

05. Lightweight blade body

Aluminum alloy knife body, which greatly reduces the weight of the knife body, can effectively reduce the centrifugal force and inertial force of the tool when rotating at high speed, not only reduces the energy consumption in the machining process, but also greatly reduces the load of the machine tool spindle, can better adapt to high-speed machining, especially suitable for the machining center equipment with weight limit.

06.Economical

2. Advantages of the blade body and blade

01. Blade body structure

Material: Lightweight high-strength aluminum alloy, ensuring rigidity and dynamic balance at high speeds of rotation.

Blade layout: multi-blade, unequal tooth pitch design, suppresses vibration, and improves heavy-duty cutting stability.

Cooling channel: internal cooling design (such as central cooling hole or blade nozzle), directly cool the cutting area and assist chip removal.

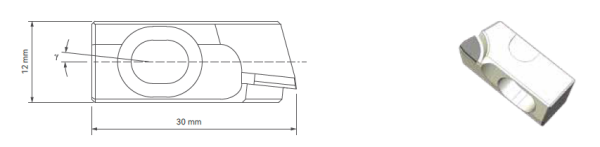

02. Special PCD tool holder blade design

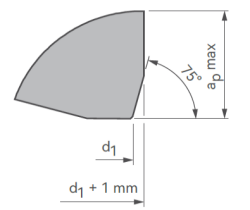

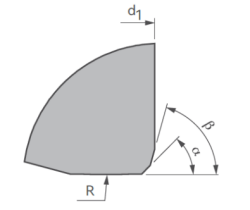

Geometrically: Optimized values of the leading, trailing, and edge angles are designed to balance sharpness and strength.

Blade forms: face milling cutter and finishing cutter.

Installation method: replaceable cutting head, support quick change.

Three, Simple and easy to understand application guidance

Recommended range of use:

Cylinder block machining: Top and bottom faces, crankshaft hole end face, oil pan junction face.

Cylinder head processing: combustion chamber plane, valve seat seal plane, camshaft hole end plane.

Please contact our after-sales service phone for specific usage:Manager Jiang 18805919865

Four, Successful Cases

With Puk Precision D250 PCD face milling cutter, the perfect combination of efficient and precise face milling processing of aluminum alloy!

Especially in the processing of car blocks/cylinder heads, it shows significant advantages in high efficiency, long service life and high precision, becoming the preferred solution for mass production. Whether it is to improve production efficiency or reduce processing costs, the D250 PCD face milling cutter from Puk Precision can bring you significant value.