Bearing hole features

With the rapid development of new energy vehicles, the Chinese people have higher requirements for various performances of automobiles, especially for the transmission performance of automobiles, and the transmission is the key component of rotation, and its bearing mounting hole plays a vital role in the transmission, not only bearing and supporting the transmission mechanism, but also ensuring the stable operation and extending the service life of the transmission through the lubrication and sealing mechanism. And this depends on the accuracy of the bearing mounting hole and the shape tolerance of the tool.

With the professional PCD team of PUK, we developed a solution for the above customer pain points, and after repeated testing, we launched the guide strip type PCD hinge (see Figure 1), which fully meets the dimensional tolerance and shape tolerance of the precision machined bearing hole, and also takes into account the cost of hole machining. It not only solves the precision problems that have been bothering customers, but also brings cost savings to customers.

Three common machining methods for high-precision holes

The processing difficulties of the bearing housing mounting hole in the new energy vehicle transmission can be expressed with three "highs", high tolerance grade, high cylinderity, and high roughness.

The processing difficulties of the case of Pu Precision are as follows (see the above picture):

Design with Puk precision knife (see Fig. 3)

Considering the serious interference, the long tool overhang, the difficulty in controlling the runout, and the high requirements for hole diameter and shape tolerance. The solutions are as follows:

Application Case

YP guide groove鉸刀; three-coordinate report

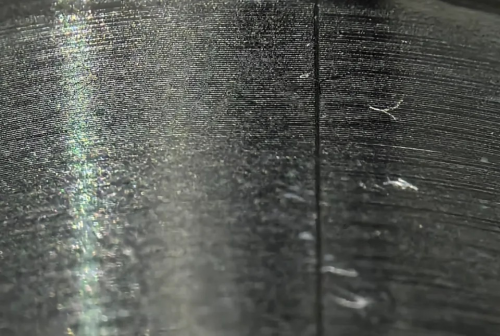

Yield point groove鉸刀 processed after hole detail amplification

Opponent guideAfter milling, the hole is enlarged